AEX324

Next unmanned generation

AEX324

Next unmanned

generation

MDO

Multi-Domain Operations

Escriviu alguna cosa...

Escriviu alguna cosa...

System MDO

The IronWake is an Open Architecture Modular System (OAMS) with Multi-Domain Operations (MDO) capabilities, integrating aircraft, ground support systems, and asset management. These systems can operate autonomously, under supervision, or manually for strategic mission decision-making, with either centralized or distributed control as strategic needs dictate. The software platform enhances this integration.

AI based UTM Software

The AI-managed human-machine interface allows for the management of available resources, preconceived tactical operations, aircraft guidance, operational resource availability, fleet control, and the formation of networks or swarms. It also handles the reception of any domain information from sensors, cameras, and alerts from operational personnel, influencing the mission leaders autonomously or under supervision to support decision-making or to act semi-autonomously, whether in deployment or conclusion.

AI applied to aircraft safety

Route

The system also manages navigation in the event of GPS loss, using inertial and visual systems for orientation until recovery, detecting potential Jamming or Spoofing interference.

Trajectory

AI systems command the missions, dynamically managing potential obstacles and routing to achieve the intended identification goals.

Energy

Energy management is also AI-driven, controlling battery consumption, estimated duration, and return, as well as battery life and anticipated recharges, achieving high precision in its management.

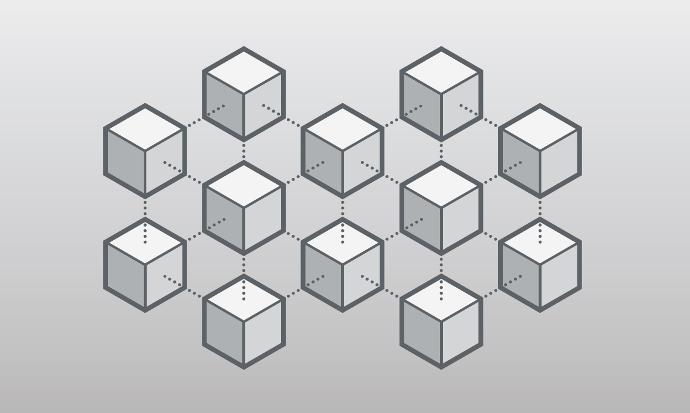

Blockchain

Similarly, it detects potential communication anomalies, reacting accordingly to the orders received, which are managed by a blockchain-based comparison, alerting the system to differences in the codes received or transmitted by different elements of the system.

Computer Vision

Detection and identification are, of course, the expected elements of all AI and CV systems. Thanks to the advanced optical system, it is possible to detect and position targets with absolute precision. On the other hand, the training of the vision systems provides the pilot with total day/night control over target identifications.

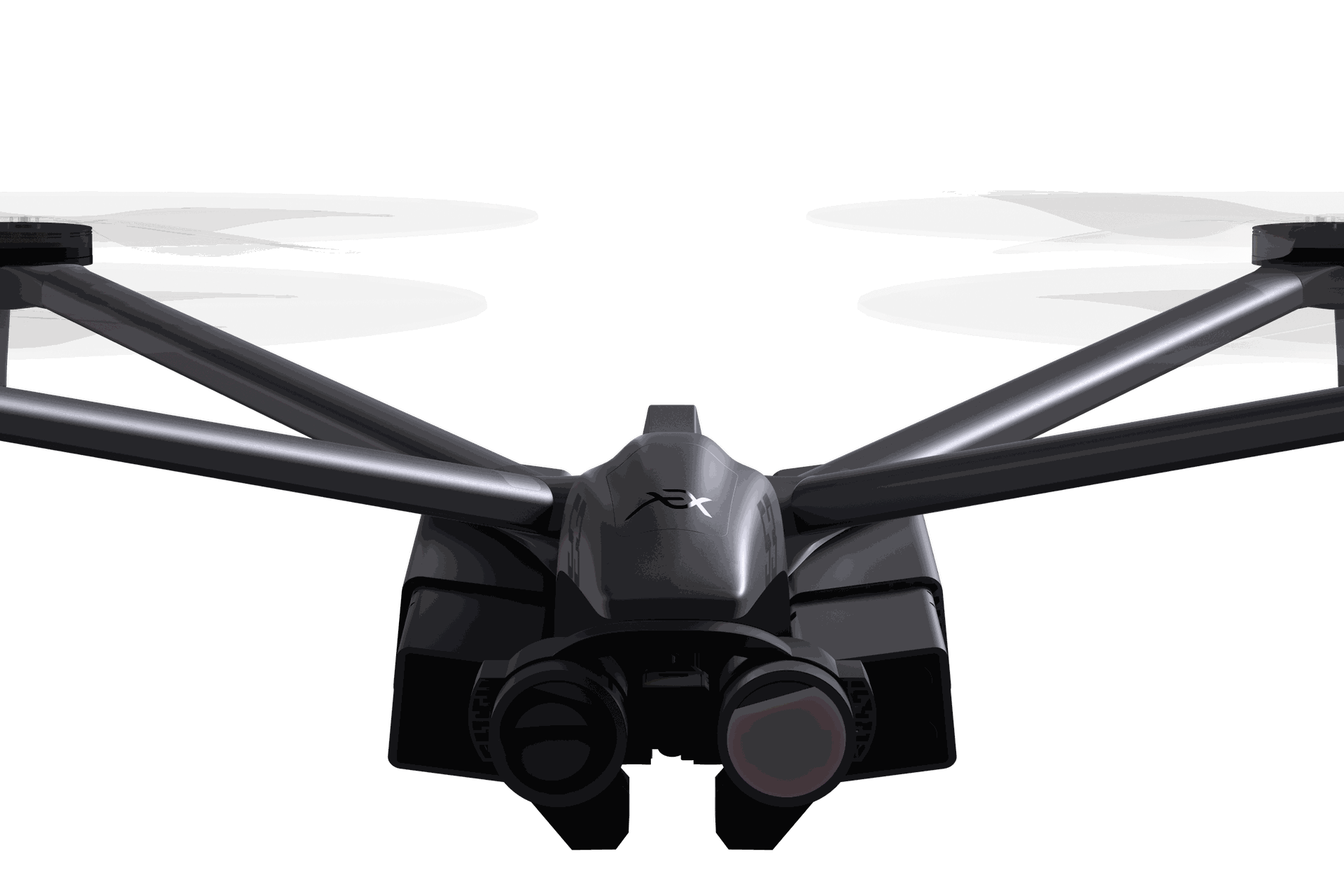

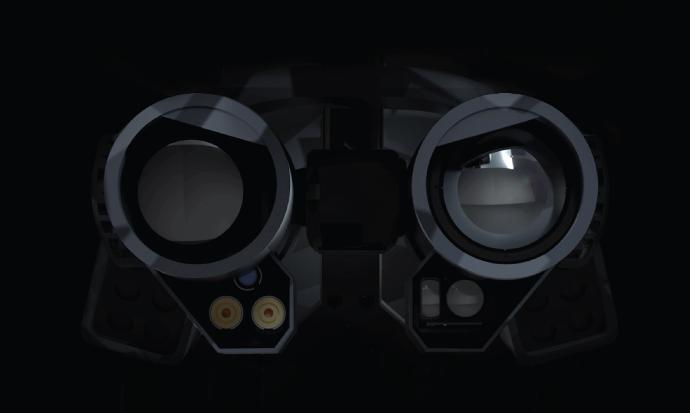

Optics & Optronics

In-house production, with thermal and day/night capacities, in addition 5000 meters of rangefinder, for a precise target positioning. It also has lens marking, and NIR laser ilumination.

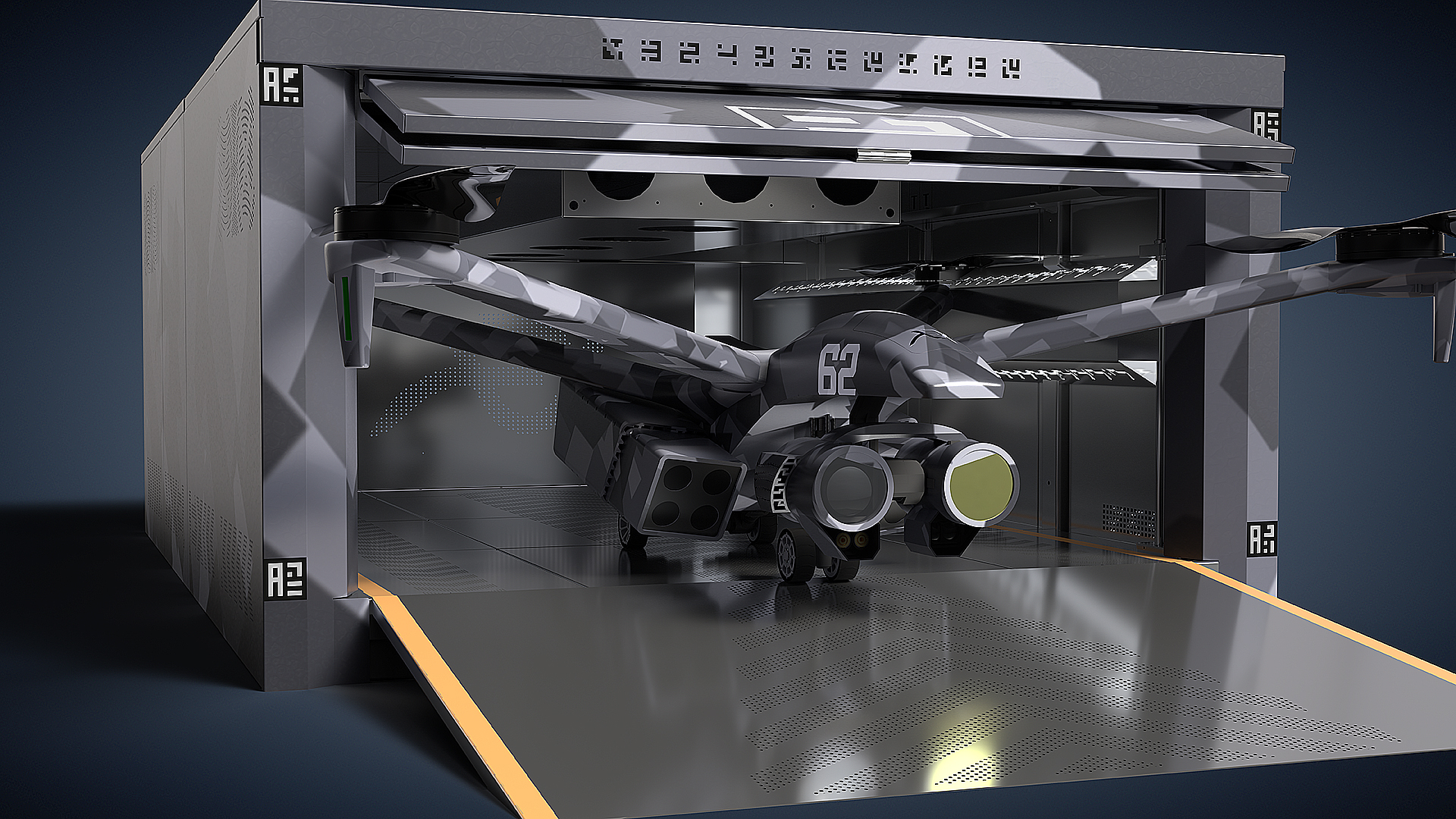

Airframe

Designed entirely in AexSpace, the fuselage withstands accelerations of 50 m/s2, thanks to its exclusive design, which combines carbon fiber, aluminium and nylon, to achieve unique elasticity and behavior.

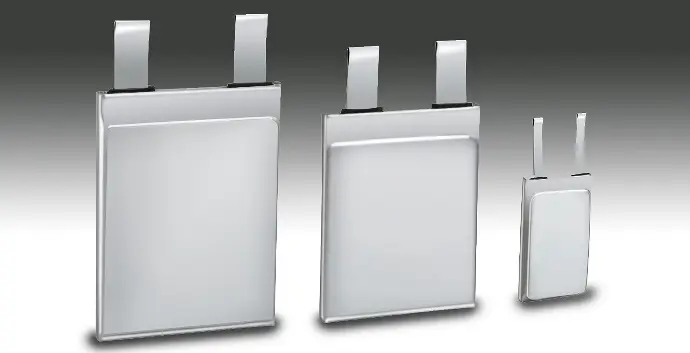

In-house production

All parts are manufactured and assembled in the company, having an internal aeronautical level quality control. Also allowing the customization of components for each client in a simple way.

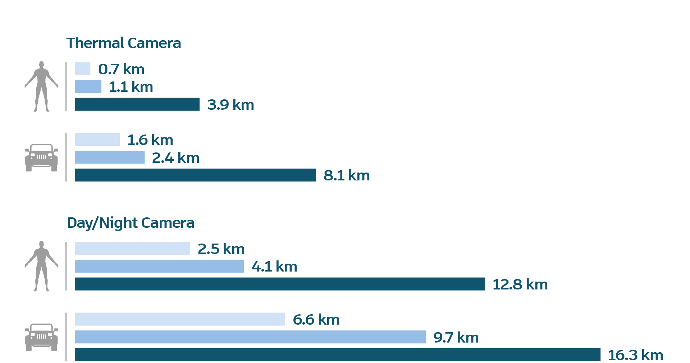

Mid-range helicopter capabilities regarding endurance and detection

Target capabilities

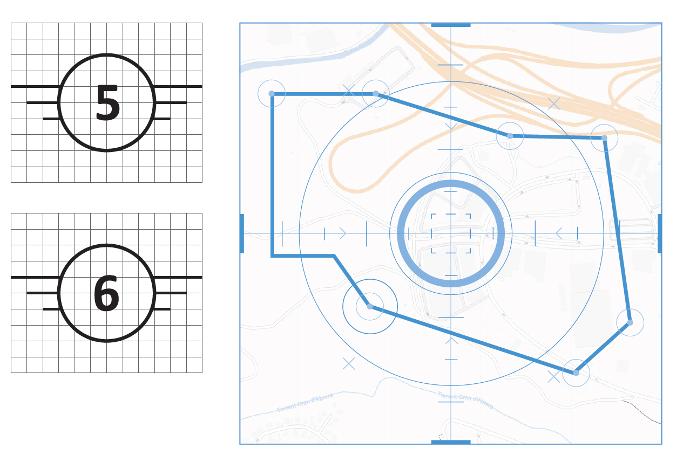

With flight capabilities ranging from 1.5 to 5 hours, they can cover operational radii of up to 50 km, while their optical systems can perform detections at 13 km (day/night systems) and at 4 km thermally.

Immersive piloting

A dual detection and piloting system aided by long-range night vision provides the aircraft with the ability to recognize potential threats, creating routes to accomplish missions, suggesting, or activating other resources or aircraft depending on the detected threat, coordinating resources for safe operations while achieving objectives.

Extreme scenarios

The A324 is designed to operate in the highest or most humid zones, where air density is very low, maintaining its operational level and performance.

Adaptable energy

Even in very hot or cold environments, its components adapt to the conditions, or can be replaced with those better suited for the mission.

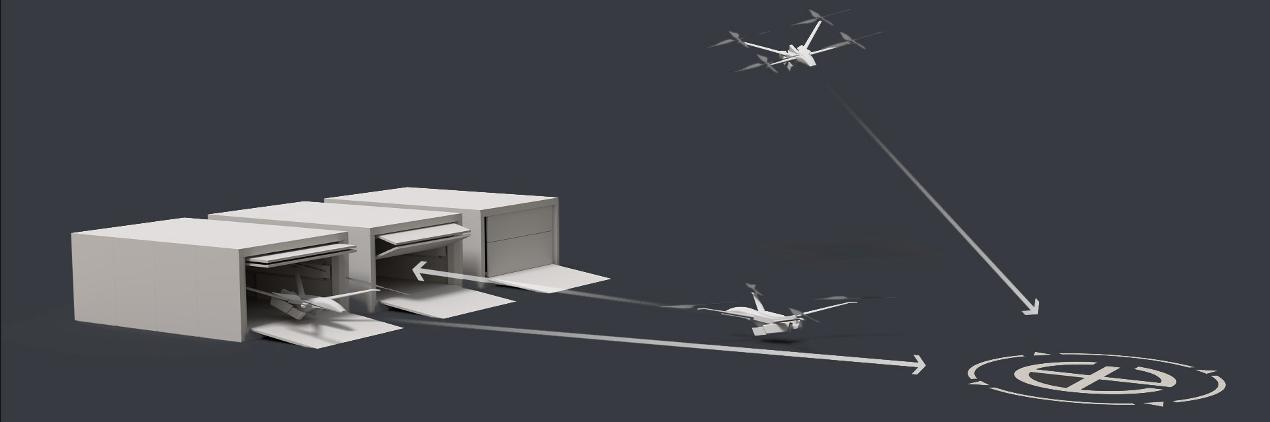

Prepared for continuous, non-stop mission coverage

In combination with the H324 ground systems, the aircraft is capable of self-sustenance and thus creates an infinite operational cycle, always being available and deployed for any mission.

C5 and C6 aircraft compliances

Communications

Redundant communication systems: Long-range C2 with licensed 5GH frequency, mid-range on open frequency, alternative mid-range radio, wireless systems based on radio or 5G.

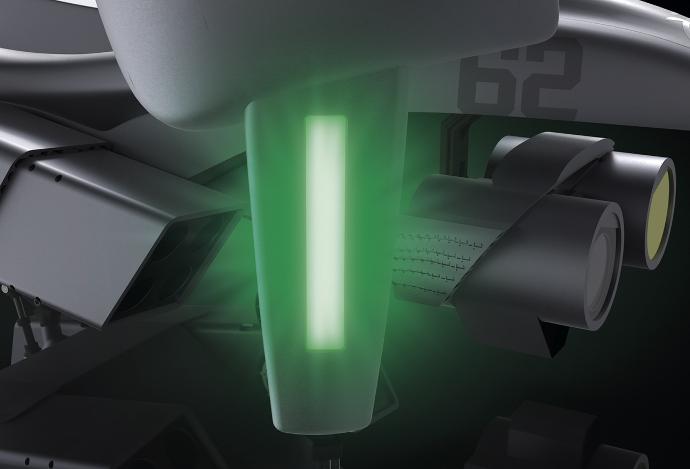

Strategic positioning

IR, Turned Off or Aeronautical. They provide the pilot with the assurance of not being easily detected in hostile environments, while meeting certification requirements for visibility in conventional operational environments.