AEX P324 PROJECTS & CUSTOM

Supporting the customer from their needs to the launch of the product.

Simulation

Digital simulation in the operations environment, to specify operational specifications and limits.

Real Operations

Real-world operations combined with mixed reality, to check system suitability and make necessary changes before production.

Customer Needs

Study of the customer’s specific needs and solution proposal that takes the following aspects into account, specifying the solution to be delivered and the timeline for subsequent phases.

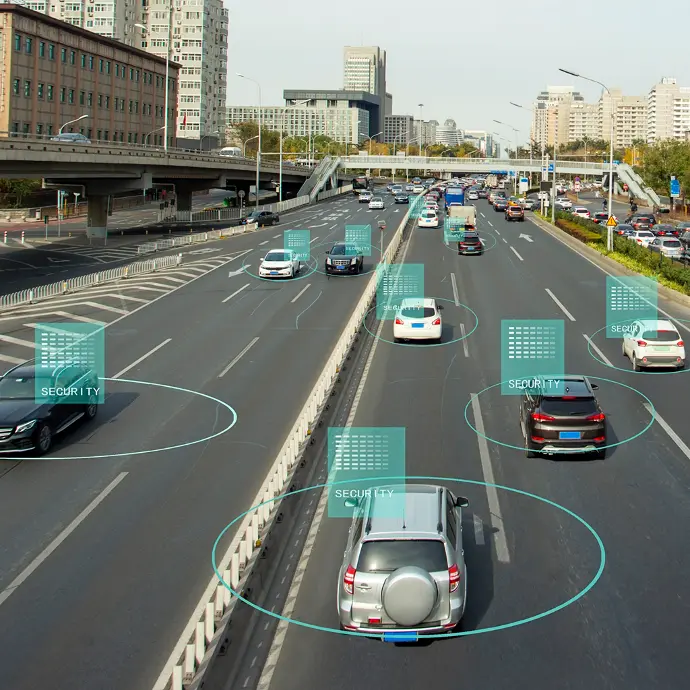

Detection

Specification of elements the customer needs to detect with any sensor to select appropriate sensors and AI.

Weather

Specific study of climate and other factors that may affect vehicle and component performance at the installation site.

Terrain

Study of the type of terrain and, for USV vehicles, the coastline and sea conditions.

Communications

Communication needs, existing networks, data density, and security.

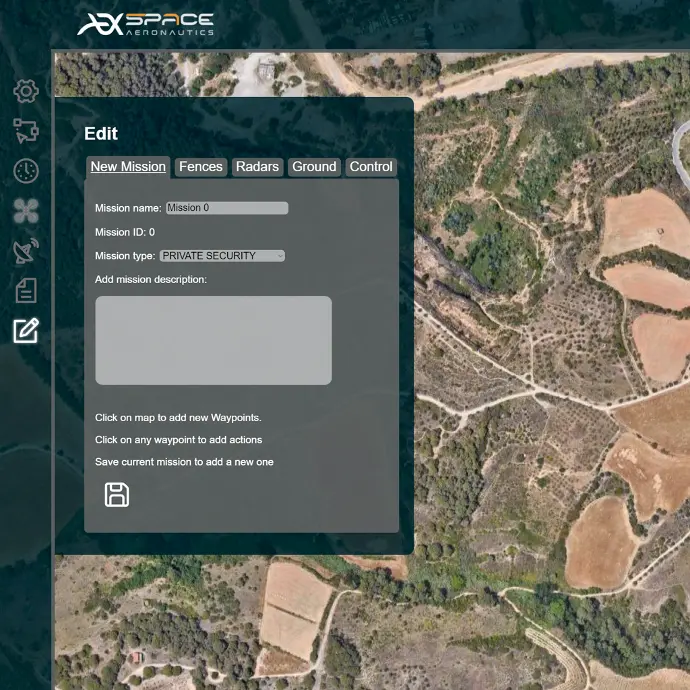

Operation Design

Together with the customer, we design the programmed operational solution for the vehicles and the level of integration with third-party software.

Hardware & Software

Proposal of vehicle type, onboard sensors, data processing hardware, AI, and software scope.

Simulation

Digital simulation in the operational environment to define specifications and operational limits, understanding potential operational difficulties and applying necessary adjustments before manufacturing the product.

AI Training

Training in target detection and operational response ensures a high level of goal achievement before real tests.

Event Simulator

Synthetic simulation of the client’s scenario(s) to check the learning level and operational success.

Weather Simulator

Simulations of different atmospheric conditions to gather data on operational limits and necessary operational adjustments.

Operations Simulator

The entire system is simulated to verify its suitability, including third-party communications and independent sensors.

Real Operations

Real-world operations combined with mixed reality to verify system suitability and make necessary adjustments before production.

Prototype Manufacturing

Prototypes or product adaptations are manufactured according to the specifications from the previous stage, with final specifications and materials. They are installed on-site as in a definitive installation, and real customer environment parameters obtained in simulators are entered into the system.

Real Operation Testing

Real operation tests certify the solutions’ proper functioning and allow for final adjustments before product shipment to the customer, who can follow the tests live to provide necessary adjustments.

Manufacturing & Installation

The product is manufactured according to final specifications from real tests; vehicles, software, ground elements, and communications are produced, strictly following specifications.

Product Delivery

Finally, the product is delivered to the customer and certified. We support the start-up of various solutions, resulting in a robust system with well-trained personnel that will provide expected results and benefits over an extended period.

Customer Staff Training

Staff are trained in system installation, maintenance, piloting operations, and strategic operational planning at the enterprise level. The customer achieves full autonomy in system utilization.